- Overview

- Description

- Technical Specification

- Photo Gallery

- Video Gallery

- Download Brochure

Overview

Overview

FABHIND Automatic Asphalt Drum Mix Plants are manufactured as per the specifications laid down by M.O.R.T & H. (formerly known as M.O.S.T.). The plants are designed and engineered to give trouble-free performance with enhanced fuel efficiency using the latest technology.

FABHIND constantly upgrade products and cater to customer the world best products, we are supplying our products to customer is exceptionally good quality and world-wide acceptable technology. We provide better after sells support with internationally known products. We provide highly modern electric controls and technology, storage facility with excellent automation support.

Asphalt Drum Mix plant is a continuous mixer in which heating of aggregates, its homogenous mixing and addition of set amount of Bitumen and Filler is done in the Drum itself. The Hot Mix Asphalt manufactured gets dispensed continuously into a truck or conveyed to a storage silo.

Asphalt Drum Mix Plants available with capacity from 20 – 120 TPH. Capacity more-then 120 TPH are as per customer’s requirement.

Description

Description

Drying Drum

The Drying and Mixing unit of the asphalt drum mix plant demands complex flight design and heat transfer technology

Robust, compact and Highly reliable

Low Fuel Consumption

Driven by 4 wheel sprocket chain/pulley

Easily operated

Alloy material is used to protect against wear and tear

The field proven unique flight design ensures total heat transfer

Mechanics :

- low maintenance cradle type drum drive.

- auto lubricant system to chain drive

- four wheel friction drive

Cold Aggregate Four Bin feeder

all bins are welded properly . bins are provided with adjustable gate and variable speed feeder drive

- feeder with maximum feeding Capacity

- easy to operate

- best technology like anti bridging for uniform flow

- Branded Vibrating motor

LOAD OUT CONVEYOR

Material From the ThermoDrum is Carried By Inclined Conveyor and transfer to any vehicle Through the hydraulically operated surge

- our belt is made of MRF / Dunlop Equipment

- Belt Scraper is provided to avoid any sticking of the mix material to the belt.

- Hydraulically operated storage hopper is provided at the discharge end of the conveyor which stores the Hot Mix and allows it to fall as mass in batches and thus avoids segregation and spillage during load out cycle.

CONTROLS

SCADA system for Feeders, Fillers, Asphalt etc

Online fault detection system

online printing facility

manual operation

all keys are provided

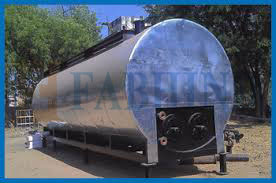

Bitumen tanks

WITH fabhind customers have options for the

- Direct Type hot oil heating system with capacity of 10 ton to 50 tons with automatic imported pressure jet burner.

- fabhind special design indirect heating tank

- The tanks are fully insulated to minimize the heat loss and are provided.

BURNER

fully automatic remotely controlled burner unit, of asphalt Drum mixing plants, has already gained an enviable reputation for its fuel efficiency

- This burner is suitable to use LDO /Diesel/FO as fuel and is fitted with remote control system to detect flame failure and have electric spark ignition system

FUEL TANK

- Fuel tank capacity ranging from 300 ltr to 10000 ltr.

Mineral Filler Unit

we offers wide range of filler storage and feeding solution depend upon the site requirements

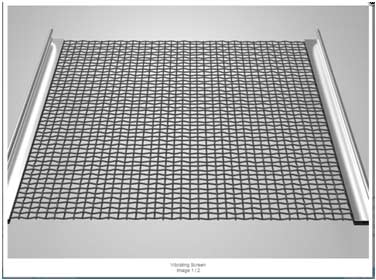

Over Size remove Vibrating Screen

fabhind provide best grade over size removal screen to remove unsafe material from machine

Storage Silo : The 30-120 Tph drum mix plants are supplied with a low maintenance cradle type drum drive. The auto lubrication system ensures proper and adequate lubrication on the chain drive thereby ensuring long life of machine with trouble free service. Optionally a four wheel friction drive, which is a standard on the 120 Tph and higher models, can be supplied

Venturi type Dust collecting System

Baghouse filter unit

We have developed a state of the art free air flow type bag house filter unit especially for asphalt application with specially treated meta aramid filter elements. This zero maintenance design keeps emissions at less than 50 mg/Nm3, which meets international pollution control norms. This environment friendly unit has low operation cost & long life.

Technical Specification

Technical Specification

| Capacity @ 3% moisture content | DM – 35 | DM – 45 | DM – 50 | DM – 60 | DM – 65 |

| Cold Feed Bins | |||||

| Capacity @ 3% moisture content | 45 tph | 60 tph | 90 tph | 120 tph | 150 tph |

| No.of Bins*/Total Storage | 4/20 m3 | 4/20 m3 | 4/25 m3 | 4/31.25 m3 | 4/37.5 m3 |

| capacity Auxiliary Drive | 1.1 kW | 1.5 kW | 1.5 kW | 2.2 kW | 2.2 kW |

| Auxiliary Conveyor Belt | 450 mm x 2.2 m | 450 mm x 2.2 m | 450 mm x 2.9 m | 450 mm x 3.78 m | 450 mm x 3.78 m |

| Charging Width Gathering | 2.55 m | 2.55 m | 3.05 m | 3.66 m | 3.66 m |

| Conveyor Drive Gathering | 3.7 kW | 3.7 kW | 3.7 kW | 5.5 kW | 5.5 kW |

| Conveyor Belt Feeding | 500 mm x 22.4 m | 500 mm x 22.4 m | 600 mm x 25.6 m | 600 mm x 29 m | 600 mm x 29 m |

| Capacity | 80 tph | 100 tph | 120 tph | 150 tph | 200 tph |

| Slinger Conveyor | |||||

| Conveyor Drive/Width | 3.7 kW/ 500 mm | 3.7 kW/ 500 mm | 3.7 kW/ 500 mm | 5.5 kW/500 mm | 5.5 kW/500 mm |

| Thermo drum Unit | |||||

| Dryer Length x Diameter | 1.23 m x 6.02m | 1.54 m x 6.40m | 1.54 m x 6.7 m | 1.85 m x 7.31 m | 1.85 m x 8 m |

| Drive Type* | Cradle type chain drive | Cradle type chain drive | Cradle type chain drive | Cradle type chain drive | 4 WD Friction Drive |

| Drive Motor | 15 kW | 18.6 kW | 18.6 kW | 30 kW | 44 kW |

| Drive Gear Box | Heavy Duty Worm Gear | Heavy Duty Worm Gear | Heavy Duty Worm Gear | Heavy Duty Worm Gear | Heavy Duty Worm Gear |

| Burner Unit | |||||

| Burner Capacity | 250 lph/3 MW | 350 lph/4 MW | 550 lph/6.5 MW | 770 lph/ 9 MW | 1100 lph/ 13 MW |

| High Pressure Burner Type | Fully automatic dual stage | Fully automatic dual stage | Fully automatic dual stage | Fully automatic dual stage | Fully automatic dual stage |

| Fuel Type* | diesel | diesel | diesel | diesel | diesel |

| Blower Connected Power | 7.5 kW | 11.25 kW | 15 kW | 15 kW | 18.7 kW |

| Bitumen Injection pump | |||||

| Capacity | 60 lpm | 80 lpm | 120 lpm | 160 lpm | 200 lpm |

| Pump Type | Hoy oil jacketed gear type | Hoy oil jacketed gear type | Hoy oil jacketed gear type | Hoy oil jacketed gear type | Hoy oil jacketed gear type |

| Drive Type | AC variable speed drive | AC variable speed drive | AC variable speed drive | AC variable speed drive | AC variable speed drive |

| Discharge System | |||||

| Load out Conveyor Belt | 500 mm x 17.9m | 500 mm x 17.9m | 600 mm x 17.9m | 600 mm x 20.3 m | 600 mm x 20.3 m |

| Gob Hopper Capacity | 1.0 ton | 1.0 ton | 1.5 ton | 2.0 ton | 2.0 ton |

POLLUTION CONTROL UNIT (Optional*)

| Wet dust type collector | |

| Type | Extremeturbulence Venturi |

| Dust emission | Less than 150 mg/m3 |

| Bag house filter | |

| Type | Reverse air flow type |

| Dust emission | Less than 50 mg/m3 |

Photo Gallery

Photo Gallery

Video Gallery

Video Gallery

Download Brochure

Download Brochure