- DESCRIPTION

- Gallery

- Download Brochure

DESCRIPTION

DESCRIPTION

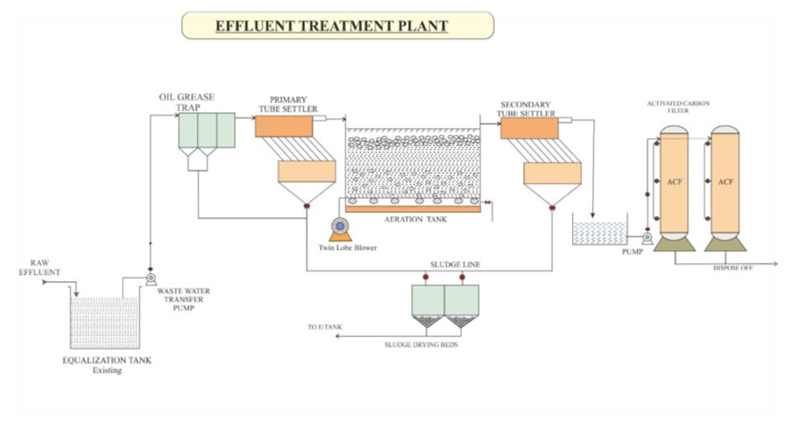

| Duty | To transfer the waste water from sump to flash mixer. |

| Driving method | Direct coupled centrifugal type. |

| Driving machine | Electric motor 0.25 h.p. |

| Matrial of construction | C.i. kirloskar |

| Capacity discharge | 0.50 – 0.75 l.p.s. horizontal |

| Head | 4 – 5 m |

| No. Of units | One |

| Make | Kirloskar |

| Material of construction | Mild Steel |

| Dimension of A/Tank | 2.0 m x 1.0 m x 1.0 m |

| Time of retention | 14.0 Hrs. |

| Oxygen transfer system | With fine Bubble with Bio-Pac Media. |

| Power required | 1.0H.P. |

| Lifting system of Effluent | With Gravity |

| Effective volume of Aeration tank | 3.25 TO 5.25 KL |

| Capacity | 1.25 m3 |

| S.W. Depth of tank | 0.5 m |

| No. Of Unit | 1 No. |

BENEFITS

- At the end of each process steam is pushed in the reactor to push out the Hydrocarbon Gas from the reactor for safety purpose & to cool down the temperature and for cleaning the pipelines during the process,

- Moisture from the oil is taken out and water generated from moisture is treated and water is reused in the system

ORANGE ROUND

It follows the pollution control norms by cleaning and recycling waste WATER.